Share to

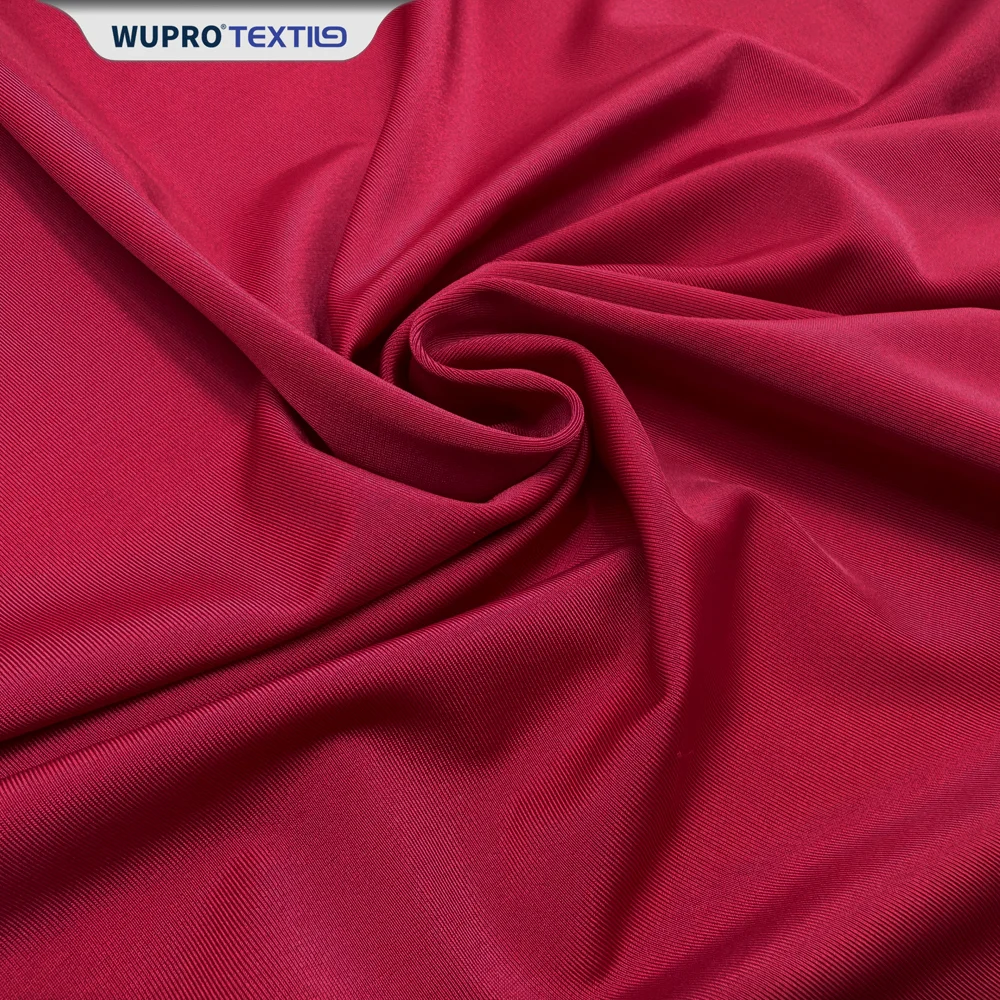

Nylon/Spandex Double-faced Knit Composite with Polyester/Spandex Omelon Fleece Fabric, Dyed & Finished (260gsm)

Item No.:

WP-GD-NA012QS-H08

Professional in product clothing of men,women and children.

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product description

-

Material structure and properties

1. Double sided cloth base layer

Composition: 80% nylon (nylon) and 20% spandex interwoven, combined with weft knitting process to form a double-sided knitting structure.

Features:

High elasticity: Spandex gives warp 300%, weft 500% tensile rate, fit the body curve and not easy to deformation.

Wear resistance: nylon fiber strength of 22.1~48.5cN/dtex, Martindale wear test > 50,000 times, scratch resistance is better than ordinary cotton ammonia fabric.

Fast drying: the water absorption of nylon is only 4%, and the moisture conduction rate is 3 times faster than that of pure cotton, which is suitable for sports scenes.2. Compound polyester ammoniacal cashmere layer

Ingredients: 100% polyester (polyester fiber) and spandex blend, after the brushed process to form 260 g /m² suede, suede length 1.5-2mm, the surface of the dense short cashmere structure.

Features:

Heat preservation: the suede-surface forms an air heat insulation layer, the thermal conductivity is less than 0.035W/(m·K), and the surface temperature can be kept stable under -10℃ environment.

Antistatic: Through conductive fiber embedding technology (such as Jiangmen Xinhui Tianrun textile permanent anti-static process), surface charge surface density < 7.0μC/㎡, to avoid winter power trouble.

Lightweight: 260g /m² weight for warmth and portability, 15% lighter than traditional polar fleece.Market application and user value

1. Typical scenarios

Outdoor sports: hardshell jacket lining, ski pants, hiking socks, providing wind protection, warmth, moisture absorption and sweat triple functions.

2. Technical barriers

Elastic retention: Through dyeing process optimization, the elastic recovery rate after 50 washes is > 90%, which is better than the industry average (80%).

Antistatic upgrade: The conductive fiber embedding technology achieves permanent antistatic, which is different from the ordinary coating treatment (wash failure twice).

Summary: The fabric achieves the balance of functionality and sustainability through the high elastic wear resistance of the double-sided brocade ammonia cloth, the warm anti-static of polyester ammonia ommi, the environmental protection of PUR composite, and the precise control of the dyeing process, which is suitable for the high-end outdoor, sports and daily clothing fields.

Nylon/Spandex Double-faced Knit Composite with Polyester/Spandex Omelon Fleece Fabric, Dyed & Finished (260gsm)

Item No.:

WP-GD-NA012QS-H08

Commit To Offer Great Solutions To 100VlP Textile&Apparel Clients

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products

Get the solution

Get the solution