Share to

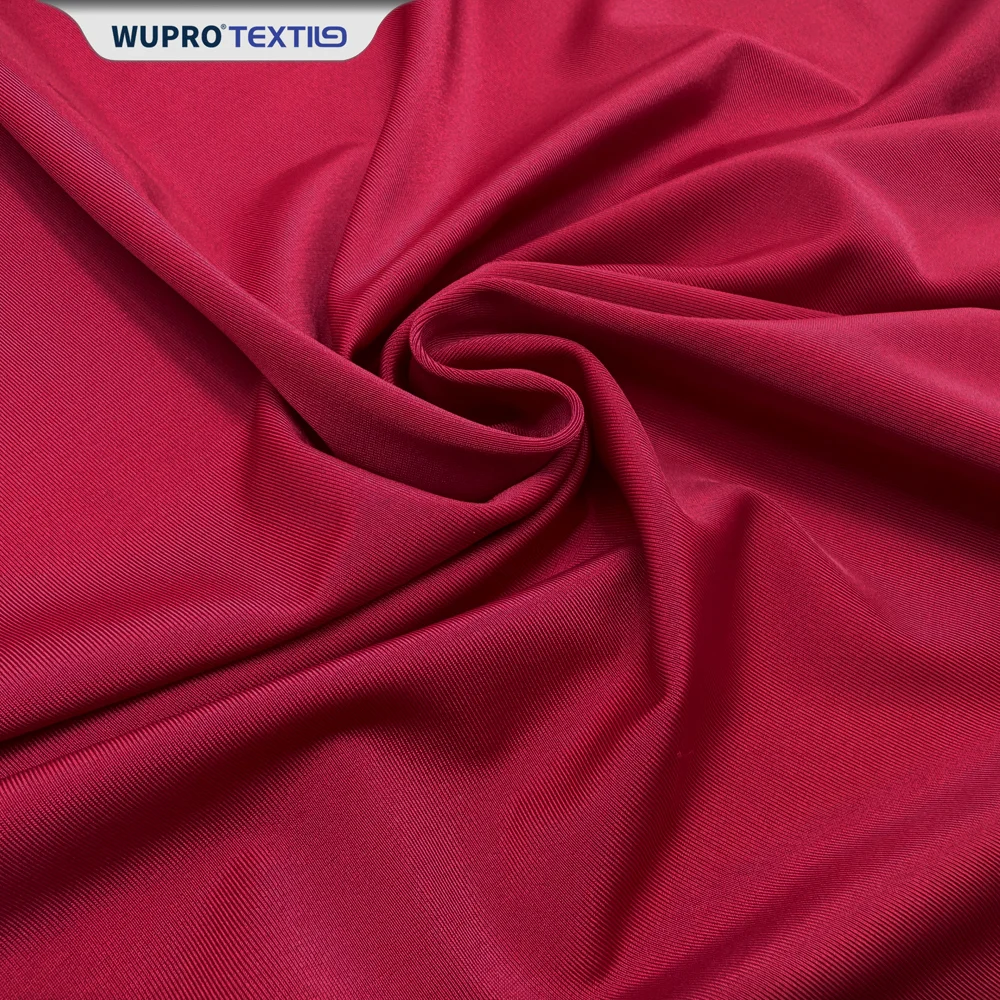

Nylon-Spandex/Supplex-TPU Laminated High-Density Fleece(10K/15K/75D)

Item No.:

WP-GT-NA002QS-H03

Professional in product clothing of men,women and children.

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product description

-

irst, material composite and process design

1. Surface: cotton brocade (Supplex® technology)

Material ratio: 90% Nylon + 10% Spandex, which simulates the microstructure of cotton fiber through the Supplex® patented process.

Technical highlights:

Cotton-like touch: The surface plain grain treatment presents cotton fine texture, skin-friendly close to pure cotton, to avoid the rough feeling of chemical fiber fabric.

Anti-wrinkle and quick drying: nylon gives fabric wear-resistant, anti-wrinkle properties, moisture absorption and quick drying efficiency increased by more than 50% compared with pure cotton;

Dynamic extension: Spandex provides 15%-20% elasticity, fits the curve of human activity, and reduces the sense of movement bondage.

2. Intermediate layer: TPU functional film (moisture permeability 10K/ water pressure resistance 15K)

3. Inner layer: 75D high-density suede structure

Yarn specification: 75D polyester filament +20D spandex core-yarn, high density knitting (28 stitches/inch) to form short suede.

Structural advantages:

Heat storage: suediness ≥300cm³/g, static air retention increased by 30%, significantly enhancing the warmth.

Moisture conduction and quick drying: The suede capillary effect accelerates sweat export to the TPU film layer to avoid moisture in the inner layer.

Wear resistance and pilling resistance: 75D high strength yarn + tight weaving, pilling grade ≥4 (5), friction resistance ≥20,000 times (Martindale test).

Second, core technology highlights

1. Functional compound innovation

"Sandwich structure" synergies:

The surface layer (Supplex imitation cotton) feels skin-friendly, the middle layer (TPU film) moisture permeability protection, and the inner layer (high-density wool) temperature lock and moisture conduction, achieving a trinity of "comfort-protection-warm".

Parameter breakthrough:

The moisture permeability (10K) and water pressure resistance (15K) simultaneously reach the industry's high-end standards (ordinary TPU film moisture permeability 3K-5K, water pressure resistance 5K-8K).

2. Lightweight and performance balanceTotal weight control: 280-320g/m² (including TPU film layer), 20%-30% lighter than the traditional three-in-one composite fabric;

Thickness optimization: ≤1.2mm (including suede), both heating and flexibility.

4. Application scenarios and adaptation products

High-end outdoor equipment:

The inner lining of ski suit, the middle layer of mountain jacket (moisture permeability + lock temperature + light weight).

Polar adventure gloves/shoe lining (low temperature resistance -40℃).

Urban functional clothing:

Winter commuter coat, cycling clothing (windproof moisture + cotton aesthetic). Business travel light down (instead of traditional gallbladder cloth, improve thermal efficiency).

Sports protective equipment:

Marathon leg warmer, ski face protector (high elastic fit + sweat management).

Five, the direction of technical extension

Intelligent temperature control version: add phase change material (PCM) to achieve dynamic temperature control (15℃-25℃ adaptation range).

Antibacterial and antiviral treatment: equipped with silver ion or graphene coating, antibacterial rate ≥99%;

Renewable material upgrade: Reduce carbon footprint by 50% with recycled polyamide (ECONYL®) + bio-based TPU.

Nylon-Spandex/Supplex-TPU Laminated High-Density Fleece(10K/15K/75D)

Item No.:

WP-GT-NA002QS-H03

Commit To Offer Great Solutions To 100VlP Textile&Apparel Clients

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products

Get the solution

Get the solution